- Shandong Loyal Chemical Co.Ltd.

- Silicone glue for curtain wall Silicone glue for kitchen and bathroom silicone glue for decoration

Home> Company News> Basic knowledge about silicone glue

Basic knowledge about silicone glue

2022-02-16 21:04:501. Classification:

Silicone glass glue can be divided into two categories from product packaging: one-component and two-component. One-component silicone adhesive, its curing depends on contact with moisture in the air to produce changes in physical properties; two-component means that the silicone adhesive is divided into two groups, A and B, any group alone cannot form curing, But the two sets of glues cure once they are mixed. One-component silicone glass glue is common in the market today.

One-component silicone glass glue is divided into two types: acid glue and neutral glue.

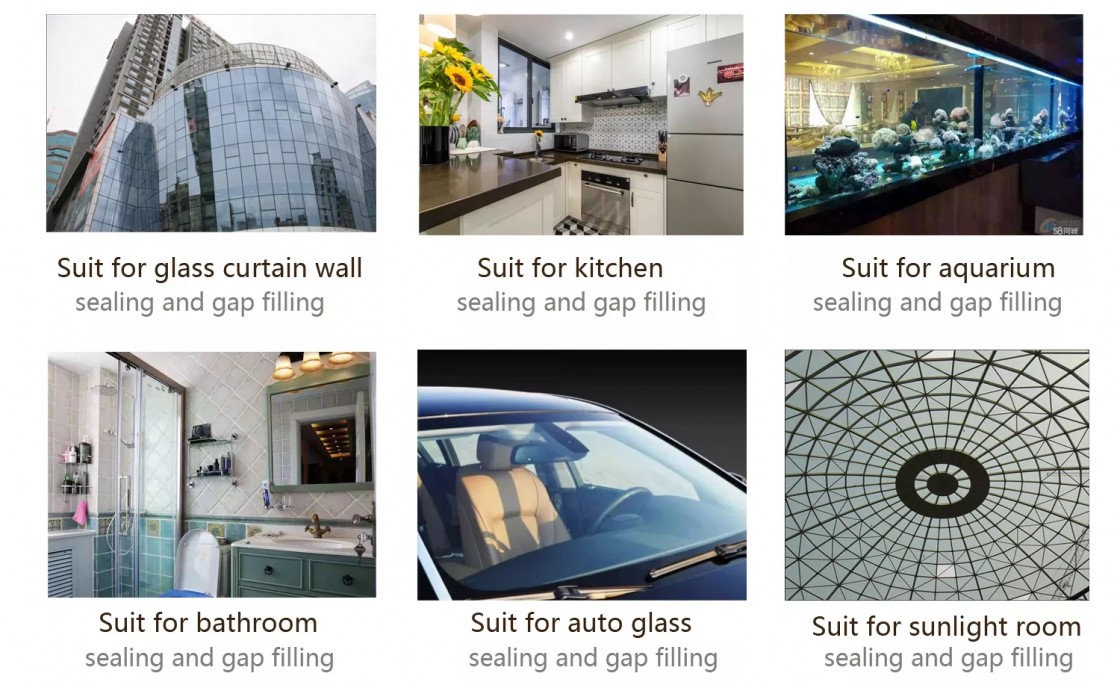

Acid glass glue is mainly used for general bonding between glass and other building materials. Neutral glue overcomes the characteristics of acid glue that corrodes metal materials and reacts with alkaline materials, so it has a wider range of applications and its market price is slightly higher than that of acid glue.

A special type of glass glue on the market is the silicone structural sealant. Because it is directly used in the metal and glass structure or non-structural bonding assembly of glass curtain walls, the quality requirements and product grades are the highest among glass glues. The market price is also the highest.

2. Brief description:

One-component silicone glass glue is an ointment-like material that solidifies into a tough rubber-like solid when exposed to moisture in the air.

Silicone glass glue has strong adhesion, high tensile strength, and at the same time, it has the characteristics of weather resistance, vibration resistance, moisture resistance, odor resistance and adaptability to large changes in cold and heat. Coupled with its wider applicability, it can realize the bonding between most building materials products, so the application value is very large.

Silicone glass glue does not flow under its own weight, so it can be used over roof or sidewall joints without sagging, slumping or running away. It is mainly used for the bonding of dry and clean metals, glass, most non-grease-free woods, silicone resins, vulcanized silicone rubber, ceramics, natural and synthetic fibers, and many painted plastic surfaces. Good quality silicone glass glue will not be squeezed out and the physical properties will not change when used below zero degrees Celsius. Fully cured silicone glass glue remains effective at temperatures up to 204°C (400oF), but at temperatures as high as 218°C (428oF), the effective time is shortened.

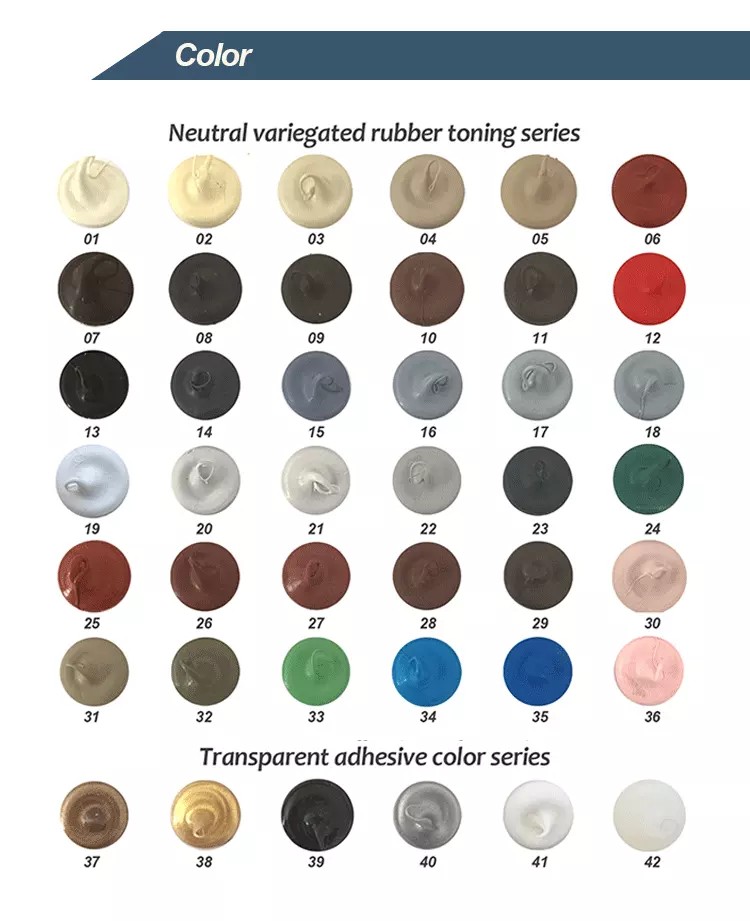

Silicone glass glue has a variety of colors, and the commonly used colors are black, porcelain white, transparent, silver gray, gray, and bronze. Other colors can be customized according to customer requirements.

3. Use

(1), Acid glass glue

1. It is suitable for sealing, plugging, leak-proof and weatherproof purposes. It is suitable for both indoor and outdoor (indoor effect is better), and the anti-seepage and anti-leakage effect is remarkable. 2. Bonding various interior decorations of automobiles, including: metals, fabrics and organic fabrics and plastics. 3. Engage gaskets on heating and cooling equipment. 4. Install ribs without screw holes, nameplates, paint and plastic materials on the metal surface. 5. Seal the window on the oven door, the flue on the gas appliance, the pipe joint, and the access door. 6. Provide instant-formed leak-proof pads for gearboxes, compressors, and pumps. 7. Seal the cabin and windows. 8. Sealing of glass windows of trailers and truck cabs. 9. Bonding and sealing equipment parts. 10. Form an anti-wear coating. 11. Mounting and filling of thin sheet metal laminates, piping networks and equipment enclosures.

(2), neutral weather resistance

1. Suitable for weather-resistant sealing of various curtain walls, especially recommended for weather-resistant sealing of glass curtain walls, aluminum-plastic panel curtain walls, and stone dry hanging; 2. Seam sealing between metals, glass, aluminum, ceramic tiles, plexiglass, and coated glass 3. Joint sealing of concrete, cement, masonry, rock, marble, steel, wood, anodized aluminum and painted aluminum surfaces. Primer is not necessary in most cases.

(3), silicone structural adhesive

1. Mainly used for structural or non-structural bonding assembly between metal and glass of glass curtain wall. 2. It can directly connect the glass with the surface of metal components to form a single assembly component, which can meet the design requirements of fully hidden or semi-hidden frame curtain wall. 3. Structural bonding and sealing of insulating glass.

4. Restrictions

All kinds of silicone glass adhesives are subject to the following restrictions: 1. It is not suitable for construction in places immersed in water for a long time; 2. It is not compatible with materials that will exude grease, plasticizers or solvents; 3. Frost or wet surfaces cannot be used Bonding; 4. The completely sealed place cannot be cured (silicon needs to be cured by moisture in the air); 5. The surface of the substrate is not clean or firm.

(1) The acid glass glue has the following restrictions:

Acid silicone glass glue will corrode or fail to bond copper, brass (and other copper-containing alloys), magnesium, zinc, electroplated metals (and other zinc-containing alloys), and it is recommended that masonry materials and iron carbide substrates Do not use acid glass glue, use this product on materials made of methyl methacrylate (PLEXIGLAS), polycarbonate, polypropylene, polyethylene and TEFLON (Teflon, polytetrafluoroethylene) will not achieve good results Adhesive effect and good compatibility. Connections that move more than 25% of the joint width are also not suitable for acid glass glue. It is also best not to use ordinary acid glass glue (except acid structural glue) on structural glass. In addition, it should not be used in places with abrasion and substantial disadvantages. Use acid glass glue. The surface temperature of the base material of the silicone acid adhesive is not suitable for construction when the temperature exceeds 40°C.

(2) Neutral weather-resistant adhesives have the following restrictions:

Neutral weather-resistant adhesive is not suitable for structural glass assembly; it is not suitable for construction when the surface temperature of the substrate exceeds 50 °C.

(3) The silicone structural adhesive has the following restrictions:

The surface temperature of the substrate of the silicone structural adhesive is not suitable for construction when the temperature exceeds 40 °C.

5. How to use

1. Use: One-component silicone glass glue can be used immediately, it can be easily punched out of the glue bottle with a glue gun, and its surface can be trimmed with a spatula or wood chips.

2. Adhesion time: The curing process of silicone glue develops from the surface inward. The surface drying time and curing time of silicone glue with different characteristics are different. Therefore, if you want to repair the surface, you must do it before the surface of the glass glue is dry. (Acid glue, neutral transparent glue should generally be within 5-10 minutes, neutral variegated glue should generally be within 30 minutes). If separation paper is used to cover an area, after applying the glue, be sure to remove it before the skin is formed.

3. Curing time: The curing time of glass glue increases with the increase of bonding thickness. For example, acid glass glue with a thickness of 12mm may take 3-4 days to solidify, but within about 24 hours, there is an outer layer of 3mm. solidified. 20 psi peel strength after 72 hours at room temperature when bonding glass, metal or most woods. If the place where the glass glue is used is partially or completely closed, then the curing time is determined by the tightness of the sealing. In an absolutely airtight place, it is possible to remain uncured forever. Increasing the temperature will soften the glass glue. The gap between metal and metal bonding surfaces should not exceed 25mm. In various bonding occasions, including airtight conditions, the bonding effect should be fully checked before the bonded equipment is used. During the curing process of acid glass glue, there will be an odor due to the volatilization of acetic acid, which will disappear during the curing process, and there will be no peculiar smell after curing.

4. Bonding: A. Wipe metal and plastic surfaces completely to remove oil stains, then use acetone to rinse all surfaces except plastic, and sand the rubber surface, then rub with acetone. When using acetone, observe the precautions for using this solvent. b. Apply the glass glue evenly on the surface of the prepared object. If you want to bond the two surfaces, you can find a place for one side first, and then squeeze the other side with enough force to squeeze out the air, but be careful not to squeeze it. out the glass glue. c. Place the bonded device at room temperature and wait for the glass glue to cure.

5. Sealing: When silicone glass glue is used for sealing, also follow the above steps, squeeze the glass glue into the joint surface or gap, so that the glass glue can fully contact the surface.

6. Cleaning: Before the glass glue is cured, it can be wiped off with a cloth or paper towel. After curing, it must be scraped off with a scraper or scrubbed with solvents such as xylene and acetone.

7. Precautions: The acid glass glue will release irritating gas during the curing process, which is irritating to human eyes and respiratory tract. Alcohol-based neutral adhesives release methanol during curing. Methanol has a potential carcinogenic hazard and is a known skin and respiratory irritant. The volatile gas can cause irritation of the eyes, nose, and throat. Therefore, this product should be used in a well-ventilated environment, avoid entering the eyes or contacting the skin for a long time (wash hands after use, before eating and smoking), and do not swallow this product. Keep out of reach of children; the construction site should be well ventilated; if accidentally splashed into the eyes, flush with clean water and seek medical attention immediately. Fully cured glass glue is not dangerous.

8. General guidelines: Before use, please read carefully the correct construction method and use of the glass glue, and please pay attention to the instructions on safe use and health hazards.

6. Storage and storage period

Glass glue should be stored in a cool, dry place below 30℃. Good quality acid glass glue can ensure the effective shelf life of more than 12 months, general acid glass glue can be stored for more than 6 months; neutral weather resistance and structural adhesive can guarantee the shelf life of more than 9 months. If the bottle has been opened, please use it up in a short period of time; if the glass glue is not used up, the glue bottle must be sealed. When using it again, the bottle mouth should be unscrewed, all blockages should be removed or the bottle mouth should be replaced.